Fischer will celebrate its 100th anniversary in 2024 and since its foundation, the company has developed into a global leader in the sporting goods industry. This is reason enough to look back at the eventful history of skiing and the role of Fischer with its innovations and successful athletes. We will also take a brief look into the future, because Fischer aims to compete with the best for the next 100 years.

From a plank of wood to high-tech

How have skis developed in terms of materials and skiing technique over the last 100 years? In the 1920s, skis were still made of solid wood, usually ash or hickory. However, with these heavy and inflexible planks underfoot, skiers were limited in what they could do on wide slopes and at low speeds. You were on the move with a long wooden pole in your hand and could only manage curves with great effort using the so-called stem turn technique. The ski boots were still made of leather and offered little support. It was only the invention of a new ski binding by the Austrian Mathias Zdarsky in the 1920s that provided stability on skis.

Now it was possible to take corners at higher speeds and on steeper slopes. In the 1960s, metal-reinforced skis came onto the market. These were lighter with a higher torsional stiffness, which allowed for more dynamics and tighter turns. At the same time, modern ski bindings were developed that increased safety. The last revolutionary step in development was the carving ski in the 1990s. The stronger sidecut fundamentally changed the skiing technique: instead of drifting, controlled carved turns were now made in the snow. Today, modern skis are made of composite materials such as carbon, fibreglass and sometimes titanal, which make them lighter and at the same time more stable. These material innovations enable higher speeds and better manoeuvrability, which has led to a further evolution of skiing technique towards more athletic styles.

Fischer: From wooden hut to ski factory

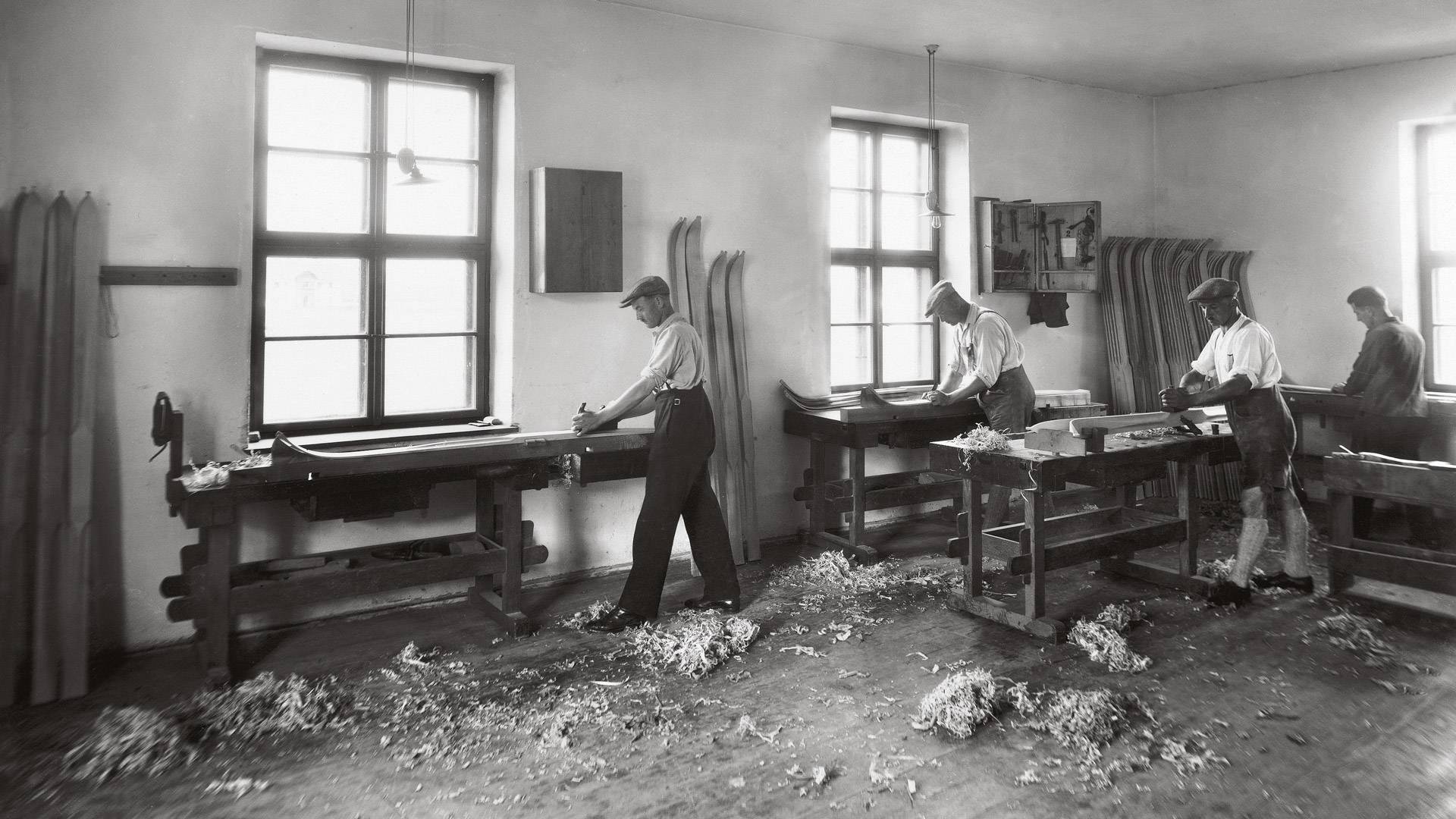

It all began in 1924 in a modest wooden hut: Josef Fischer founded the Fischer & Größlbauer ski factory in Ried. Initially, sleds and handcarts were also made. Fischer developed the machines for these himself due to a lack of funds. By 1925, the first skis were already being produced – each pair a unique item. The improvised workshop in the wooden hut soon became too small and in 1929, Fischer bought a disused wainwright's workshop nearby. With better equipment and more space, and using resilient wood from mountain ash, Fischer was able to produce more and better skis.

During the Second World War, Fischer produced skis for the military and deckchairs for the military hospitals, which helped the company to survive this difficult time. After the war, ski production picked up again and Josef Fischer Junior pushed through the switch to ski gluing despite internal resistance. His father was sceptical of the project, which ultimately became a huge success. Expansion continued and new company premises were gradually purchased. Despite often difficult financial circumstances and setbacks, Fischer persevered with a great deal of commitment and new ideas. Josef Fischer died in 1959 and his son led the company into a new era.

Fischer: From innovations to titles

Under the new management, Fischer developed into one of the largest and most modern ski factories in the world. Marketing was professionalised, exports grew and public interest increased as skiers were equipped. In 1960, the first metal ski, the Alu Steel, was launched on the market, which won gold at the 1964 Olympics under the trained legs of ski racer Egon Zimmermann. This victory changed Fischer's image from a low-cost children's ski manufacturer to a highly technical and successful racing ski brand. Numerous titles in alpine and Nordic skiing followed and Fischer established itself as a global brand in the sports world.

One of the most legendary success stories was Franz Klammer's Olympic downhill victory in 1976 in Kitzbühel. However, the ‘hole ski’ that Fischer had planned as a world premiere remained in the basement despite an agreement on Klammer's initiative. Klammer won Olympic gold on the Streif under incredible public expectation and the greatest possible pressure – and on an ‘old’ Fischer ski! To date, Fischer has taken a total of over 150 World Cup victories in alpine skiing and, together with the Nordic disciplines, 720 medals at the Olympics (since 1976). Visionary technological developments such as Vacuum Fit for perfect boot fitting, Hole Ski technology for optimised control and carbon skis in the 2000s are still driving the company's continued success today.

Fischer: an eye on the future

For the future, the company continues to focus on innovation and the development of new technologies in skiing. However, the family business, which currently employs around 1,100 people, is not only successful in the ski sector. As a manufacturer of sports textiles, tennis equipment and ice hockey sticks, Fischer also stands for the highest quality in these areas.

For SPORT 2000, Fischer is one of the most important equipment partners with a shared history that has been written for over 25 years. The first contract signed in 1999 laid the foundation for a successful and trusting partnership. Since then, SPORT 2000 and Fischer have jointly realised numerous innovations and projects that have had a lasting impact on the world of sports. This long-standing collaboration is not only proof of the high quality and reliability of Fischer products, but also of the shared commitment to providing athletes with optimal equipment and promoting their passion for sports.

We wish them all the best for the next 100 years!

‘Our commitment to innovation, quality and customer satisfaction is as strong as ever, and we look forward to continuing to shape the future of sport in the next century.’ Franz Föttinger, CEO of Fischer

‘Our success is driven by motivated and qualified employees who are not afraid to take matters into their own hands and break new ground.’

Josef Fischer